So you’re interested in getting a laser machine? Good choice! Laser engraving and cutting is certainly the wave of the future, and it’s no wonder – lasers are precise, elegant, and efficient. The demand for laser machines has increased by 6% since last year alone.

Image source Endurance Lasers https://endurancelasers.com/color-metal-engraving/

Laser machines can be used for an immense variety of purposes, including engraving photos onto wood or metal, cutting out materials for DIY projects, adding text to fabrics for fashion design purposes, etching designs into the glass for advertisements, engraving onto leather goods, and more.

Before looking at what you need to consider before buying a laser machine, it’s of importance to know that if you own your 3D printer, you can easily turn it into a laser machine with much ease by buying the appropriate 3D printer attachment like the Endurance Laser. So 3D printers are not just confined to 3D printing, It can also be used in laser cutting and laser engraving.

The Endurance Lasers gives your 3D printer the capability to cut and engrave almost anything you want. You can do amazing things such as engraving/cutting on metal (stainless steel), glass, leather, etc. They are compatible with most 3D printers and CNC machines out there. A small investment will get you an incredible machine upgrade. If you already own a CNC router & router bits, then there’s no need to buy another expensive machine just to get laser cutting capabilities!

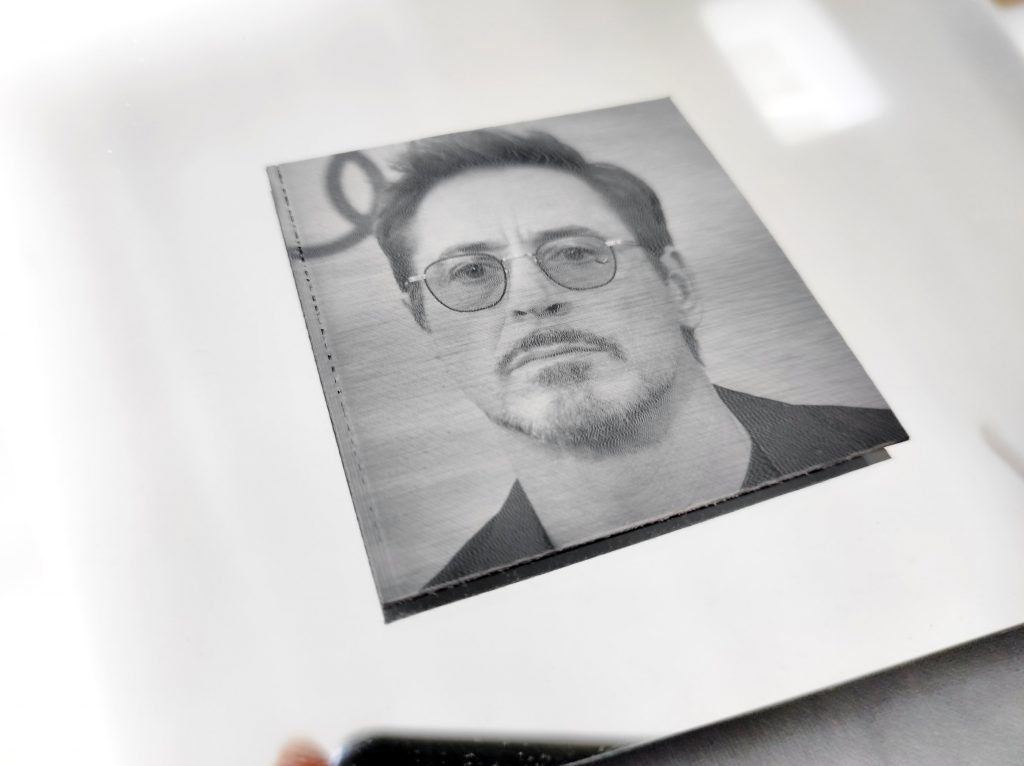

Photo Engraving on Black PLA plastic using Endurance Lasers

If you are planning to buy your Laser Machine and you might be wondering what to consider. Follow along!

Do your homework

Before you buy a laser machine, make sure you’ve done your research on what types are available, the differences between them, their prices, and which features are really essential to have. I know it can be overwhelming when you’re trying to decide which model is best for your needs and budget, and that’s why I’m here to help you sort through the confusion.

What materials do you need to engrave or cut?

Some laser machines work for a variety of materials, such as glass and metal. Some are better equipped for one particular kind of material, like leather or fabrics. Some can even engrave on organic materials like wood and bamboo.

If you’re unsure about the types of materials you need to work with, it’s a safe idea to choose a machine that has either the option of working on multiple types of material like the Endurance Lasers — or one suited for the material you’re working with most.

Do you need it to engrave or cut?

Some machines can do both, while others specialize in one task or the other. If you aren’t sure if the laser machine is the right choice for your project, check which applications are best suited for each type of function.

If you want a wide range in flexibility, you might opt for a laser machine that can cut and engrave in the same session. If you’re going to be using it for specific purposes, however, one or the other will probably do just fine.

Power Output of the Laser

Before choosing which laser to buy, you need to be sure of its power output. This is key as it will determine the type of work that you can do. So you can do your research to know the power output your specific task will require and this will help you decide on which laser with what amount of power output to buy. You need also to be cautious that you may not fall for fake lasers with false power outputs so that you may not be disappointed later on.

How much workspace do you have?

Laser machines come with different-sized fields of engraving. Before you decide on a model, measure the area where you will be using it to make sure it will work for your space.

How much do you have to spend?

There are many options available in price, so find one that fits within your budget comfortably while still offering all the amenities and functions you’ll need. Although laser machines can tend to be pricey due to their high quality, there are models available for less than $1,000 USD.

Is this just going to be a short-term purchase or should I invest in something more durable?

Since laser machines can run upwards of $10,000 depending on which features are included with the package, it could be worth looking into warranties and service packages before you make your purchase.

Manufacturers’ warranties almost always include a clause that allows the machine to be repaired, but sometimes you have to pay for shipping and handling if it breaks down or malfunctions.

On top of that, some machines have a limited warranty period of just 1-3 years, while others offer up to 5 years guarantee on parts and services. These longer-term warranties not only improve customer satisfaction, but also give you a better idea about the quality of materials used in production.

Do I know anyone else who might want this?

You could save yourself a lot of time and hassle if you buy a laser machine with features like automated bed leveling sensors—which allow any number of users to operate as long as the material is placed in the same spot each time.

This saves you from having to reposition or move heavy materials around when engraving, which you’d have to do for manual machines if more than one person was using it.

Are you willing to learn how to use this machine?

Although many laser machines come with automated features and ease of control, they can still be complicated to handle. Before you purchase any machine, consider how much time and patience you’ll need to learn its functions and features before you start working with your project. Purchasing a learning kit at the same time as your machine lets you take advantage of free technical support and hands-on instruction prior to making full use of your new equipment.

Where are you going to put the laser cutter?

Industrial machines take up a lot of space, which might not be an issue if you’re setting up shop in a garage or shed. If you don’t have the needed space, are you willing to sacrifice valuable space in your shop/garage for the machine?

Maintenance cost

Lastly, consider the cost of maintenance. Is it an easy machine to maintain, or is it difficult for less-experienced techs to work on? Does the company offer training? There are companies out there who don’t even offer training, so if you can’t find any information about the machine’s ease of maintenance, it might not be worth it to buy it.

If you look into all these options before buying, you’ll have a much easier time finding the perfect laser machine for your needs.

Hope this article was helpful!