CNC machining works on subtractive technology. Unlike 3D printing, a solid block of material is used to begin the process in CNC machining. For the final shape, the process removes the extra materials from the surface of the workpiece using a variety of sharp rotating tools or cutters.

CNC machining is flexible in manufacturing small jobs and medium to high volume production as well. Its excellency offers repeatability, high accuracy, the usability of various materials, and fine surface finishing.

Additive Manufacturing (AM) or 3D Printing processes with one layer of materials added to the build parts. AM technique does not have any special features or cutting tools. Initial setup costs are less than CNC machining. In this article, you can find the functional parts and prototypes of both CNC and 3D printing. It will help you to consider the right technology for your application.

Let’s see the basic process of the two methods.

- CNC machining uses block materials at the beginning of the process, and it finishes the whole work removing material from the surface of the workpiece using cutting fixtures.

- The most important element of 3D printing is powder or resin.

Let’s see the similarities first:

- CNC and 3D printing are both more time-consuming processes than moulding, and both techniques are efficient enough to meet the aim.

- Various materials can be processed.

- CNC and 3D printing both have expertise in the production of small batches at affordable prices.

Differences between 3D printing and CNC machining are mentioned below:

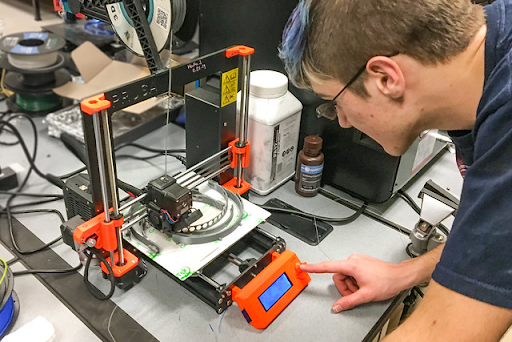

3D printing. Image source: USDA

- Different materials

Generally, most of the materials CNC can be processed are plastic and hardware materials.

Currently, among all processing materials that are essential for 3D printing, photosensitive resin is the most important component.

- Different material utilisation rates

3D printing is based on additive manufacturing technique, which is responsible for high material utilisation rate.

CNC machining does not require cutting the whole workpiece to get the final product, so the material utilisation rate is less than 3D printing.CNC carving machine takes high-speed moulded objects from some solid substances like; wood, metal, plastic.

- Processing comparison

Program:

3D printing: A driver software has been incorporated in the 3D machine to calculate the printing time.

CNC machining: requires professional programmers and operators.

Quantity of processing:

3D printing: In this technique, one tray is enough to complete multiple parts printing without any manual support.

CNC machining: One single part can be processed at a time.

Processing time:

3D printing: From the time of innovation of 3D printing, printing time has become fast.

CNC machining: Programming and processing time are longer than 3D printing.

Process complexity:

3D printing: 3D machine parts can process complicated jobs and structures.

CNC machining: For the complex surfaces, the machine parts need to be programmed multiple times and disassembled.

Different precision and success rates:

3D printing: This process gives you high-quality printing with great accuracy. Its success rate is also high.

CNC machining: There are possibilities of failure of poor fixtures and human error.

- Product usability

3D printing: The moulded products are low-strength in character, and they have minimal wear resistance.

CNC machining: Here, moulded products act opposite. They are high-strength products with great wear resistance.

Based on the above discussion, the fact is that CNC machining is easier to manufacture large parts with comparatively simple structures, whereas 3D printing is mainly used for the production of small jobs with thin walls. It is also efficient for various complex appearances.

Let’s take a look at the advantages:

3D printing advantages:

- The materials and the element’s requirements are less. The difficulty level is low in making complex internal parts. The post-processing works are limited.

- 3D printing produces objects of any shape directly, which minimise the cost, time, production cycle and maximise productivity.

- It works on technique additive manufacturing that does not cost high for complicated parts production. Material and machine cost are the two important factors in 3D printing. A design to be 3D printed is prepared easily in a 3D design software then 3D printed.

CNC advantage:

3D printing technology is rapidly developing. This is the reason behind CNC processing techniques becoming less demanding, but it is still dominating the prototype industries for specific reasons. They are:

- CNC can do industrial design products irrespective of all functions.

- CNC can deal with a vast range of materials. For functional parts, similar materials or corresponding components are available to meet the production need.

- It is suitable for large parts manufacturing. From an economic point of view, it is much cheaper than 3D printing. For the advanced application of materials and adhesives, the built parts get more strength after splicing.

- The surfaces of the workpiece are being treated only after the CNC machine is processed manually. The effect is more or less close, sometimes even higher.

The reasons behind the industries still prefer CNC first:

Based on the above-discussed facts, we assume that 3D printing is more advantageous than CNC. Still, in reality, CNC has grandly been accepted in industries and is a preferable process for enterprises. The reasons are:

- Economic advantage: When manufacturing large and heavy parts, CNC costs are cheaper than 3D printing.

- Processing standards: CNC machining has been used over a long period and developed gradually with a complete set of industrial standards in the industries. This development includes tools, the control system, microprocessing fixtures, and spindles. On the other note, 3D printing has not yet evolved any industrial moulding structure for production.

- Awareness: Many companies are entirely new to this 3D technique. They do not keep faith in this advanced technique because they are familiar with traditional processes like; CNC. They are confident and trust CNC to generate their production. Though there are some techniques about CNC machining that many people are not aware of; for example, how one can make a CNC machine using a 3D printer.

How to Turn a A 3D Printer into a CNC Machine

If you didn’t know, you can not only use your 3D printer for 3D printing, but you can also use it for laser engraving and laser cutting. It might sound like rocket science, but with the right tools and techniques it can easily be achieved.

To turn a 3D printer into a CNC machine, you will need to have a laser module. There are various lasers available in the market that you can buy for example the laser endurance lasers. Before buying one, you should consider the laser power as well as the materials that it can engrave and cut.

Music instrument made using Laser Endurance

Ease of Selection

The choice of technology depends on their applications, and the user’s requirement determines it. If you need a piece of straightforward advice, then go for CNC machining if you can use it; otherwise, use 3D printing. In some cases, the combined technique of additive and subtractive manufacturing processes is more beneficial to achieve your aim.